Giovanni Dore, project manager at Movyon, talks about the options available when implementing advanced technologies to upgrade free-flow tolling systems, wherever you are in the world, overcoming challenges to take full advantages of all the benefits on offer.

Giovanni Dore, project manager at Movyon, talks about the options available when implementing advanced technologies to upgrade free-flow tolling systems, wherever you are in the world, overcoming challenges to take full advantages of all the benefits on offer.

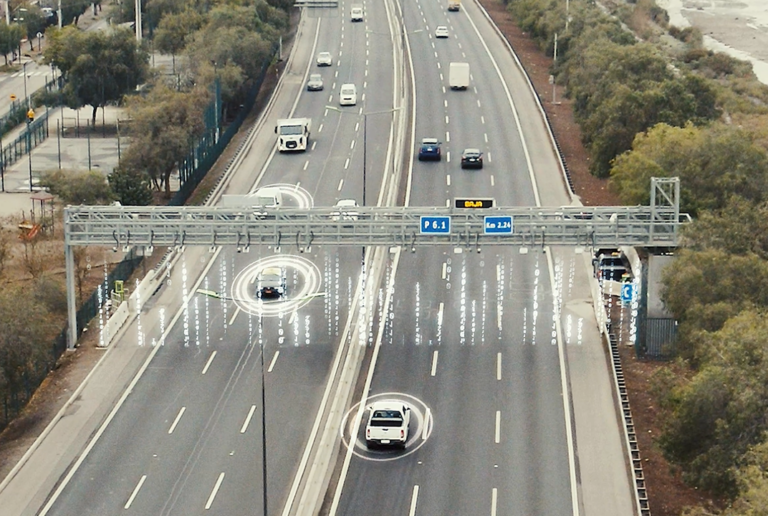

Toll booths are disappearing rapidly from roads all around the world in favor of congestion-busting, pollution-reducing, free-flow solutions. But the decision to go free-flow cannot be undertaken lightly, as operators must be certain that any alternative solution will protect revenues in a cost-effective way. Moreover, once a free-flow solution is installed, attention must be paid to maintaining and, when the time is right, upgrading systems, to ensure maximum efficiency.

One player with vast experience of developing, installing and upgrading free-flow tolling systems all around the world is Movyon, an Italian ITS solutions provider, which also acts as a centre of excellence for research and innovation for Autostrade per l’Italia Group, the largest road concessionaire in Italy.

Where to begin?

A starting point for the installation of new free-flow solutions is an analysis of the market penetration of tolling tags. Depending on the location in the world, tags can be either RFID or DSRC-based onboard units. “If there is a low distribution of tags among users then free-flow implementation becomes more challenging because there is more pressure on enforcement,” says Giovanni Dore, project manager at Movyon. “When we talk about multilane free-flow system, we are actually talking about tolling and enforcement in a single system. Since the concessionaire cannot force the user to buy a tag, the implementation of a accurately performing enforcement system becomes important.”

Enforcement on toll roads is almost exclusively performed by ALPR (automatic license plate recognition) systems. In recent years this has evolved into pre- or post-pay options where users can set up an account linked to their license plate and make payments on account to avoid fines. Nevertheless, in jurisdictions where tags have any penetration at all, it is generally more cost effective to focus on them as the main method of revenue collection, as the level of accuracy is expensive to replicate with ALPR. Moreover, many customers are often more comfortable with tags. Some countries and US states are resistant both culturally and legislatively to pay-by-plate due to privacy concerns.

Hardware requirements

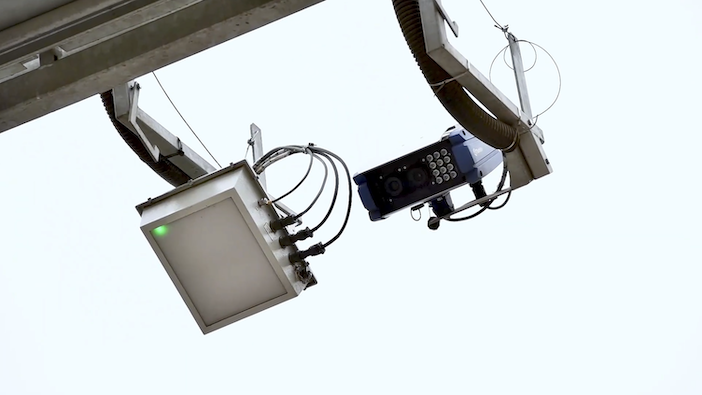

In terms of the hardware on gantries, there are a number of subsystems required. The first is for tag detection, for which Movyon uses at least one radio frequency detector per lane – either RFID (ISO/IEC 18000-63 @860 MHz) or 5.8GHz DSRC (CEN EN 15509 or ETSI ES 600274-1).

“In Chile we installed more than one antenna per lane in order to have overlapping coverage,” says Dore. “We also installed the ALPR enforcement subsystem – two cameras for each lane, one for the front plate and one for the rear. Then there is a video subsystem that includes other cameras – monitoring cameras that help us to track the vehicles that are a passing through the gantries. Then there is the classification subsystem, which is extremely important for the proper working of the gantries.”

Vehicle classification, essential in order to verify validity of tags or plates, can be done in a variety of ways. Movyon uses a laser-based system. “For each lane of the gantry, we install a couple of lasers that allow us to reconstruct the volume of the vehicles that are passing using our software,” explains Dore. “We use third-party hardware but our software for the 3D reconstruction is crucial.”

Part of what makes Movyon’s classification software so important is its adaptability, meaning different systems of classification can be designed for different clients, depending on their demands. In total 32 different classes of vehicle can be identified with the Movyon system, which can also include axle counting for jurisdictions where tolling categories are defined by vehicle-axle number as well as vehicle volume. Axle counting can be done either with lasers or cameras. All of this is managed by Movyon’s classification software, which runs on an edge controller.

“Usually we have a gantry cabinet, into which we run all the cables carrying data from the devices. When we have to monitor five lanes of traffic there are a lot of devices,” says Dore. “Then, depending on the location of the gantry we can install a second cabinet at the base in a technical shelter or basement, which houses the controller where our software engine runs.”

In difficult locations where a roadside cabinet could be potentially damaged or vandalised Movyon also has the capability to put all the hardware, including controllers, up on the gantry.

“But you have to put a climatic cabinet with batteries up on the gantry,” says Dore.

Edge processing means there is only a light data load to send onwards to the back office. It also means that, should there be a problem with the communication network, Movyon’s gantry controller can store all the relevant tolling information, essential for revenue, and send it to the back office when communication systems come back online.

The importance of testing performance

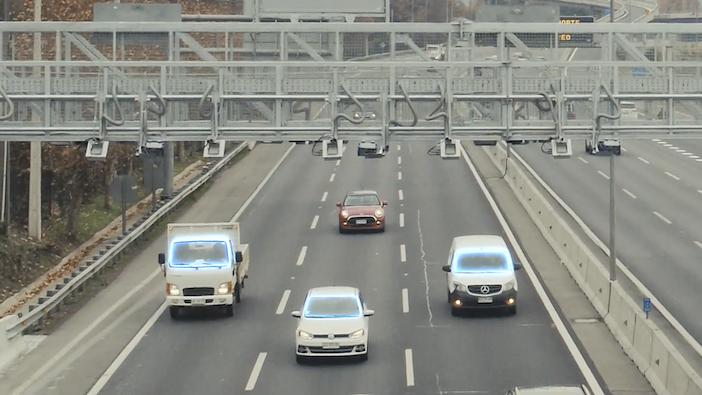

A key challenge for any free-flow tolling technology provider is to get the concessionaire to trust the system prior to installation. And so, reliability and accuracy must be proven. To this end, Movyon has test gantries in two live, real-world highway sites in Italy, as well as one off-highway site. In these locations the robustness of different systems can be demonstrated, according to specific client requirements.

“We have two gantries on the highways, one close to our offices in Florence and one close to Rome,” explains Giovanni Dore, project manager at Movyon “On these we install and test all our free-flow solutions. On the gantry close to Rome we have replicated an installation we have recently undertaken in Chile, using their local DSRC standard, which is different from the Italian tolling systems.”

“When we win any bid, we perform the FAT – Factory Acceptance Test – inviting our client to view it on one of the gantries, which cover up to eight lanes. It enables the client to see the solution we will provide to them in the near future, working,” says Dore. Movyon is also able to use the gantries to test new technology ahead of new system design.

Why Movyon?

With so many different tolling providers out there, there are several features that set Movyon’s solutions apart from the competition. Particularly it is a company experienced at developing customized solutions and also at rolling out brownfield upgrades with a very low impact on client operation.

“The project in Chile is a renewal of nearly 40 existing tolling gantries,” explains Dore. “We were able to remove the devices of the old provider that had been there for over 10 years to install our system. And this was done without any loss of income for the concessionaire. In this case we don’t provide the commercial back office, we adapt to the back office already present, that usually does not need to be renewed as often as hardware. We provide the hardware and Movyon protocols and then we translate the data into the language of the back office of the client – the front-end proxy (FEP).”

Movyon also provides full diagnostic and management systems, both at the gantry and network level “The gantry diagnostic and management system is useful for maintenance who can connect directly to the gantry and check what is happening. It is also useful during set up for the fine tuning of the system.”

Movyon also provides central monitoring for all the gantries in a network. “We have a huge software team, that provides to concessionaries all the tools that are needed to monitor, evaluate and manage the full system,” says Dore.

Add to this, the fact that Movyon is part of Autostrade per l’Italia Group with a very long experience in providing advanced ITS solutions and constantly investing in R&D and innovation, helps to ensure easy access to cutting-edge technologies, full advanced testing and integration of any system and local requirement. And it’s easy to see why the company is rapidly growing in tolling all around the world.

The supplier feature was produced in association with Movyon