Christoph Klauser, business development manager for traffic solutions at Kistler looks at how weigh-in-motion and structural health monitoring can help to protect sensitive infrastructure.

Bridges all over the world can be efficiently monitored with weigh-in-motion (WIM) and structural health monitoring (SHM), extending their service life and, in a worst-case scenario, preventing their collapse. The Kistler Group installs solutions of this kind worldwide, continuously developing its sensors and measurement technology further to contribute to the safety and longevity of bridges in the most efficient manner possible.

Since it became possible to calculate bridges with increasing accuracy in the 19th century and new materials also became available – beginning with cast iron and steel, then reinforced and prestressed concretes – the number of bridges constructed has increased all over the world. It is evident today that many of these have aged considerably. These conditions often lead to the collapse of bridges, despite regular inspections and repairs.

The Fern Hollow Bridge in Pittsburgh (USA), an approximately 135-meter-long three-span steel bridge over a forest ravine, collapsed on January 28, 2022. Fortunately, no fatalities occurred, although several vehicles, including a bus, were involved in the collapse. How can accidents of this nature be avoided, and which technologies are available to protect bridges more effectively?

Ensuring observance of weight limits with weigh-in-motion

Restrictions relating to velocity and vehicle weight are frequently encountered on bridges, particularly where heavy traffic is involved. The strain experienced by the structure increases exponentially as vehicles become heavier, with trucks and heavy commercial vehicles in particular causing excessive stress to roads and bridges.

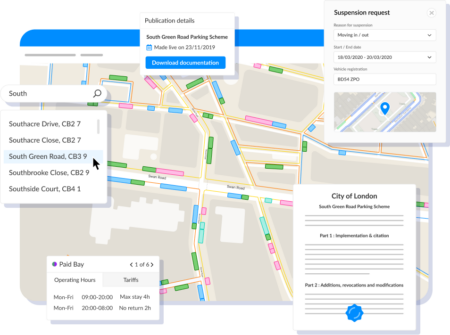

However, speed and weight restrictions unfortunately only have a limited effect as they are frequently not observed. A WIM system is particularly effective in ensuring compliance with regulations. In addition to measuring the overall weight of the vehicle, sensors integrated directly in the road surface also determine the real extent of significant axle loads.

This is achieved in moving traffic at normal speeds (heavy traffic up to 120 km/h, vans up to 140 km/h) and in several lanes.

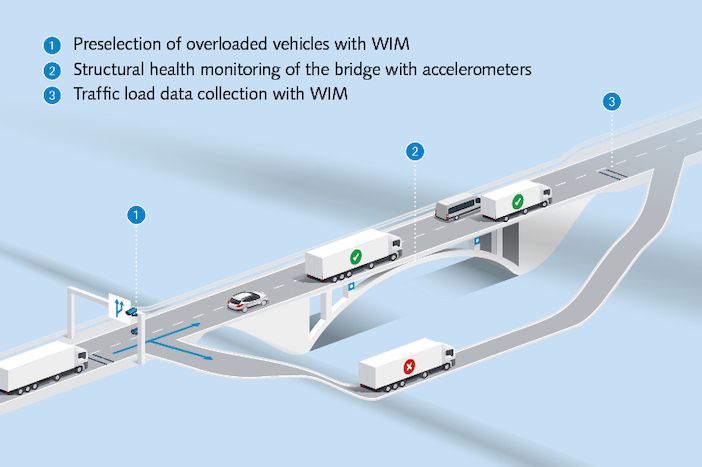

Three specific advantages that contribute to effective bridge protection are derived from this:

- The acquisition of weight-related vehicle data provides an accurate basis for calculating the actual load on the bridge and the remaining service life (instead of estimates). Overloaded vehicles that exceed the permissible overall weight can be prevented from crossing the bridge (so-called preselection).

- The collection of fees is also possible, depending on domestic legislation in the particular country.

- The WIM system can also be combined with further sensors and cameras to, for example, detect speed, the condition of tires and vehicle dimensions, thus contributing to increased road safety on the bridge.

WIM for efficient international bridge protection

KiTraffic series Weigh In Motion systems from Kistler are deployed for this reason on many bridges around the world, collecting traffic data and ensuring applicable rules are observed. A WIM system from Kistler has been monitoring the spectacular El Carrizo bridge in Mexico since the summer of 2018. Overloaded vehicles are preselected and prevented from crossing the structure that, at 226 meters, is the second-highest bridge in North America.

Older and smaller bridges can also be protected with WIM systems. A solution of this kind was used in Austria for a road traffic bridge spanning a very busy long-distance line operated by Austrian Federal Railways (ÖBB).

Due to the presence of a sawmill nearby, the bridge had already been damaged by heavy timber transports. KiTraffic Statistics helped to reliably detect trucks that were frequently massively overloaded and, in cooperation with the authorities, these were ordered to pay a fee. Overloading of the bridge reduced correspondingly within a short period of time.

Real-time condition monitoring thanks to structural health monitoring

Despite the usefulness of WIM systems in providing modern bridge protection, they cannot provide any information on the actual condition of the structure. Further technologies frequently associated with condition monitoring and SHM therefore play a significant role.

This involves the installation of sensors at key positions on the bridge to, for example, record vibrations or changes in the construction material. The quality of data is decisive for reliable condition monitoring.

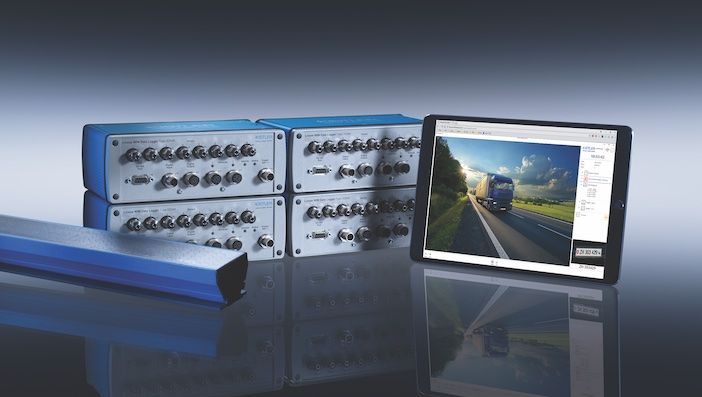

The entire measuring chain from sensor to software must be examined in this respect to ensure that what is seen on the monitor is as accurate a representation as possible of what is currently happening on and, indeed, “in” the bridge. With regard to real-time monitoring, particular attention must be paid to the achievement of high-quality signal transmission and data acquisition.

In addition to strain sensors and accelerometers as individual components, the Kistler Group also provides complete solutions from sensor to cloud. K-Beam accelerometers from Kistler have been installed in the piers of the Great Belt Bridge in Denmark, a structure which has spanned the Great Belt strait in the Baltic Sea since 1998.

These compact sensors continually record changes in natural frequency in real time that could indicate a possible deterioration in the condition of the bridge. Turnkey systems consisting of sensor technology, the KiDAQ data acquisition system and a customized software dashboard are also increasingly employed. Solutions of this kind enable authorities and bridge owners to monitor the condition of these structures continuously and reliably, and they provide support when planning everything from maintenance management to new constructions.