Michigan-based Storch Magnetics has invented a product that can expedite pothole repairs by dramatically reducing the flat tires experienced by Department of Transportation (DOT) highway repair crews.

There were 738 total motor vehicle fatalities in tire-related crashes in 2017, according to the National Highway Traffic Safety Administration (NHTSA). In addition, an October 2015 report released by the National Transportation Safety Bureau (NTSB) indicated that each year, about 33,000 passenger vehicle tire-related crashes occur in the USA, resulting in about 19,000 injuries.

The NTSB has publicly stated that a majority of tire-related crashes are preventable, and much more can be done to prevent tire-failure-related accidents. According to AAA, motorists suffer more than 220 million flat tires each year in the USA, or seven flats occur every second.

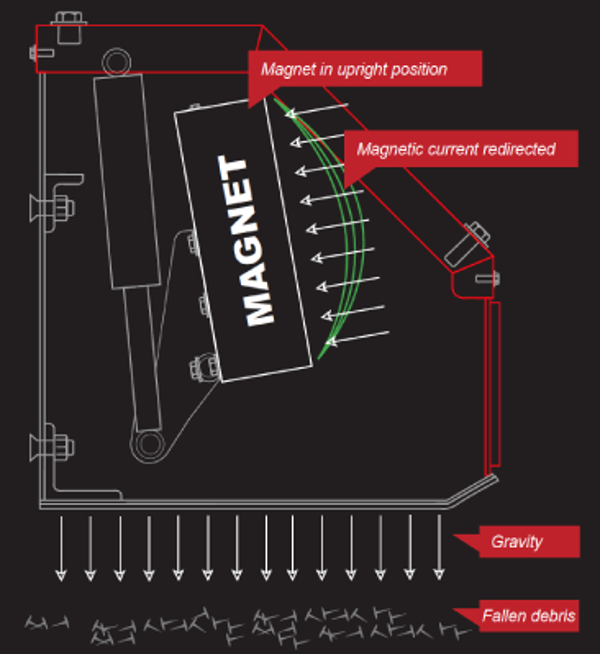

Nails, screws and other metal debris on the roadways and highway shoulder can cause flat tires, which is particularly debilitating during DOT’s pothole repair season, causing maintenance vehicle flats, slowing down roadworks and costing taxpayers’ money. Mounted on the front of maintenance vehicles, Storch’s SuperMag is a powerful and durable industrial-sized magnet that removes damaging and debilitating debris from any surface.

Nails, screws and other metal debris on the roadways and highway shoulder can cause flat tires, which is particularly debilitating during DOT’s pothole repair season, causing maintenance vehicle flats, slowing down roadworks and costing taxpayers’ money. Mounted on the front of maintenance vehicles, Storch’s SuperMag is a powerful and durable industrial-sized magnet that removes damaging and debilitating debris from any surface.

The SuperMag unit is the first magnet of its kind that can be front-mounted on an existing snow plow mount. The permanent magnet is hydraulically actuated, hinging upward and away from the working surface. It can be fitted to a lead vehicle on a pothole repair team so that hazardous items are magnetically removed from the road, virtually eliminating the threat of a flat tire from road debris. It is designed to last generations with less than 1% of magnet loss per 100 years. SuperMag is easy to operate and can be raised and lowered like a snowplow, and operators can turn the unit on and off without even leaving their vehicle.

“Pothole repair and road maintenance crews experience an average of one flat tire every three hours on the road, said Storch Magnetics’ CEO, Matt Carr. “It’s amazing how much hazardous debris you encounter on the shoulder of our roads. This is particularly true after snowplows and sweepers have pushed these items off to the side when clearing snow and ice this winter.

“Pothole repair and road maintenance crews experience an average of one flat tire every three hours on the road, said Storch Magnetics’ CEO, Matt Carr. “It’s amazing how much hazardous debris you encounter on the shoulder of our roads. This is particularly true after snowplows and sweepers have pushed these items off to the side when clearing snow and ice this winter.

While it can cost up to US$750 to repair and replace a tire on a maintenance vehicle, the more significant cost is the lost time of the idled crew. At less than US$15,000, one SuperMag in a road commission fleet can save taxpayers hundreds of thousands of dollars over the years. The amount of debris that exists on many roads is one of the hidden dangers that doesn’t always get addressed. SuperMag allows these crews to remain effective and efficient. Plus, you have the added benefit of picking up this dangerous debris for other motorists.”

Bob Griffis, director of operations and deputy managing director at the Jackson County Department of Transportation, commented, “Before using SuperMag, we were experiencing a flat tire about 90% of the time we had a crew heading out for pothole repair. By using SuperMag for approximately one year, Jackson has already paid for the cost of the magnet just on tire repair savings alone. The amount of money we have saved just on tires has been unreal. We’ve taken SuperMag out to crash sites to sweep up debris there as well.”

Bob Griffis, director of operations and deputy managing director at the Jackson County Department of Transportation, commented, “Before using SuperMag, we were experiencing a flat tire about 90% of the time we had a crew heading out for pothole repair. By using SuperMag for approximately one year, Jackson has already paid for the cost of the magnet just on tire repair savings alone. The amount of money we have saved just on tires has been unreal. We’ve taken SuperMag out to crash sites to sweep up debris there as well.”