A leading automotive technology suppliers is developing reliable, ‘digital slipstreaming’ systems for automated trucks, which it intends to put into series production by 2020. The legal framework is likely to be the only obstacle to widespread truck ‘platooning’.

Continental is paving the way for the wide-scale adoption of digitally connected truck convoys with its development of the ‘electronic towbar’. The company will present basic platooning technology at this year’s IAA Commercial Vehicles show in Hannover, Germany, on September 22-29.

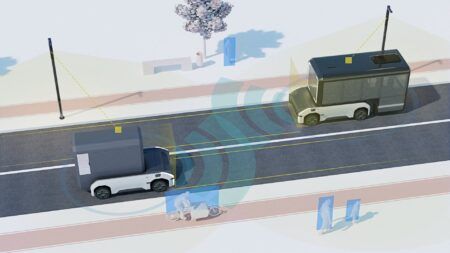

The company is developing components and systems for the series launch of platooning technology by 2020. Although the technology used is complex in detail, the basic principle is very simple. Continental is focusing on an interoperable internet platform, which trucks from different manufacturers and fleet operators can use to form an electronic convoy on the freeway. The drivers in the convoy are supported by fully automated driving systems, and braking and sensor data are transmitted wirelessly from the lead vehicle to the following vehicles. Due to this ‘electronic towbar’, Continental envisages the possibility of initially reducing the distance between vehicles from 164 to 50ft (50-15m) at a speed of 50mph (80km/h). Development experts even predict that, in the long term, it will be technically possible to safely reduce this distance to only 33ft (10m), which will further reduce the space required for them on the road.

If only 50% of the annual mileage of a truck, totaling 93,200 miles (150,000km), were driven in convoy, every coupled truck would be able to save 880 gallons (4,000 liters) of diesel per year. One of these convoys would reduce annual fuel costs by over US$10,120 (9,000) per year and enable the fleet operator to reduce its CO2 emissions by 24kg per hour with a convoy of three trucks. As the first step, Continental is working on the technology for highly automated convoys comprising a lead truck being followed by one or two additional trucks using the electronic towbar.

“With platooning, the truck, which is electronically coupled with the lead vehicle, consumes up to 15% less fuel thanks to safe slipstreaming. Even the lead vehicle drives up to 3% more efficiently on account of the reduction in air turbulence,” explained Dr Michael Ruf, head of Continental’s commercial vehicles and aftermarket business unit. “It is important to create a legal framework that permits the minimum spacing within a platoon to be reduced if the technological capabilities of the trucks allow for it. An opportunity like this, which can bring about huge fuel and, consequently, CO2 savings, must not go to waste. We are currently doing our homework with regard to the development of systems for production, and striving for swift clarification of the framework conditions. The legal framework is the final hurdle before the introduction of platooning.”