UK-based simulation software specialist, rFpro, has developed a new technique that helps to overcome the safety concerns around testing and developing connected and autonomous vehicles (CAVs) on public roads, and could enable their regulatory approval before widespread deployment.

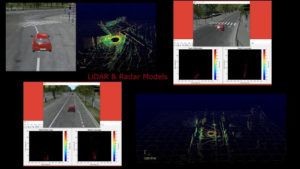

By developing a physical model of the real world, known as the Ground Truth, rFpro can accurately test the vehicle’s perception of its surroundings, which has not been previously possible. The new system will enable legislators to define an approval process for a vehicle within a completely virtual environment, certifying it as safe to use on real roads. The technique is already being used to validate vehicle safety in Euro NCAP (European New Car Assessment Program) tests. A current UK government project, dRISK, is also using the rFpro software to validate sensor models against the real world so they can be correlated with actual sensors. The program is seen as an essential stepping stone towards end-to-end validation of autonomous systems through simulation.

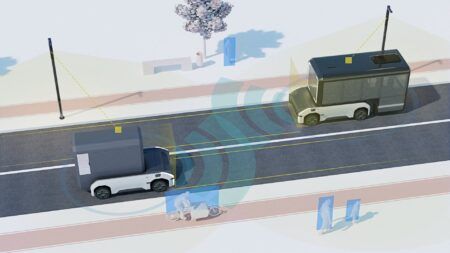

The ability to evaluate a CAV’s sensors’ perception during simulation is important because future legislation is likely to dictate the virtual testing and approval of any autonomous system before its use on public roads is permitted. The whole system must therefore be tested in a fully-representative virtual environment, not just elements of it. Due to the vast number of miles required to validate an autonomous vehicle in a huge number of different environments, it is not feasible to do this in the real world. Sensor perception is the most challenging aspect because it requires a physically accurate virtual world with high levels of correlation to the real world and physically modelled sensors.

“Most system modelling begins with ideal sensor models in order to validate the algorithms and control systems of the vehicle, but this bypasses any limitations in the sensors themselves,” explained Chris Hoyle, rFpro’s technical director. “Difficult lighting conditions, or the reflections in a shop window can corrupt a sensor’s perception of the vehicle’s surroundings, leading to potentially catastrophic errors. Thorough validation of a CAV or ADAS-equipped vehicle must include the sensors’ ability to recognize and characterize the features of its environment. Physical modelling means simulating the materials and properties of every object encountered by the vehicle and its onboard sensors, rather than just an abstract representation of it as used by most systems.”

“Most system modelling begins with ideal sensor models in order to validate the algorithms and control systems of the vehicle, but this bypasses any limitations in the sensors themselves,” explained Chris Hoyle, rFpro’s technical director. “Difficult lighting conditions, or the reflections in a shop window can corrupt a sensor’s perception of the vehicle’s surroundings, leading to potentially catastrophic errors. Thorough validation of a CAV or ADAS-equipped vehicle must include the sensors’ ability to recognize and characterize the features of its environment. Physical modelling means simulating the materials and properties of every object encountered by the vehicle and its onboard sensors, rather than just an abstract representation of it as used by most systems.”

Hoyle added, “With several years’ experience of creating digital twins of city streets, rural roads, proving grounds and test tracks, we understand the complexities of modelling features like changing weather conditions or road surfaces. With our system, minute road surface differences are accurately modelled, which means ride comfort can be assessed. Due to the infinite inputs possible from sensors, there is a big emerging need for autonomous system test engineers making use of simulated software. Previously there has been around a 1:1 ratio of software engineers to test engineers in the automotive sector. We believe this is moving closer towards the avionics sector where there are around five test engineers per software engineer to ensure the safety of passengers.”