Highways England (HE) is expanding its use of automated technologies with the trial of a time-saving road marking robot that is saving drivers on the country’s busiest roads from hundreds of hours of disruption.

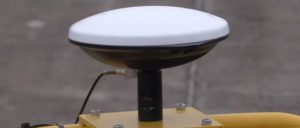

The new autonomous machine uses precise positioning technology to mark out where white lines need to be painted on new or resurfaced roads. Ordinarily, pre-marking road markings is a time-consuming job, calculating the positioning of the markings and walking several miles to spray or chalk them on the road. Around 250 drivers currently drive into roadworks every month, putting workers’ lives at risk, but by using the robot, road workers spend far less time in the road and are at less risk of an accident. Bending down to pre-mark roads by hand can also raise the risk of back injuries. The robot also boasts improved accuracy and can mark the road faster.

So far, the robot has already saved hundreds of hours of working time on various HE projects across the country, including the UK’s biggest road upgrade, the £1.5bn (US$1.9bn) A14 Cambridge to Huntingdon improvement. It also recently pre-marked eight miles (12.8km) of the M6 in Staffordshire in four hours, which would usually take two engineers over a week to complete. Benefits elsewhere include saving 27 hours of working time marking three miles (4.8km) of hard shoulder on the M4 in Berkshire, 77 hours covering five miles (8km) of the M6 in Warwickshire, and six hours working on two miles (3.2km) of the M1 in Leicestershire, with further work done on the M60 smart motorway at Manchester. Besides helping drivers and its safety benefits, the robot also enables roadworkers to focus on completing other essential work on each project.

“We’re always looking at innovative new ways of working, which can help road users, and make our projects more efficient while supporting improved engineering. With safety our top priority, the time savings the robot can provide, coupled with removing our operatives from a potentially hazardous situation, make it a great solution,” explained Julian Lamb, HE’s construction director on the A14, where the robot has been trialled. “We’ve also been working with a self-driving dumper truck on the project, completing trials of these new technologies to help us deliver our ambitious programme of roads improvement more quickly, safely and efficiently. These technologies are also supporting new jobs, with the engineers of tomorrow needing to learn new skills such as programming this autonomous equipment.”

The robot has been so successful that specialist contractor WJ, which adopted the technology for it to complete the pre-marking, has now invested in a second one to help complete more of its work. By completing roadworks faster, the robot will help contribute to the goals of reducing congestion, improving journey times, and supporting economic growth, while cost savings can be used to provide more or better-quality road-building materials.

The robot has been so successful that specialist contractor WJ, which adopted the technology for it to complete the pre-marking, has now invested in a second one to help complete more of its work. By completing roadworks faster, the robot will help contribute to the goals of reducing congestion, improving journey times, and supporting economic growth, while cost savings can be used to provide more or better-quality road-building materials.

Wayne Johnston, WJ Group’s managing director, said, “I am passionate about changing the way we work in this industry and the WJ Robotic PreMarker represents a real step change. However, it is just a starting point, we will continue to invest in research and development to find better, more efficient and safer ways of working.”