The Toyota Research Institute (TRI) has unveiled its next-generation automated driving research vehicle, Platform 3.0, at the CES 2018 event in Las Vegas, Nevada, with the car boasting 656ft (200m) of perception around a full 360° radius.

Created at Toyota’s Prototype Development Center, the new platform, which is built on a Lexus LS 600hL, combines greater technological capabilities with new harmonized styling that integrates the automated vehicle (AV) technology into the model’s design. TRI approached development of a new research platform with three core principles:

• Elevate perception capabilities to be an industry pacesetter among AVs;

• Blend the sensing equipment into the vehicle design with a distinct appearance that is sleek and elegant;

• Package the AV technology in a manner that is easy to reproduce for building a fleet at scale.

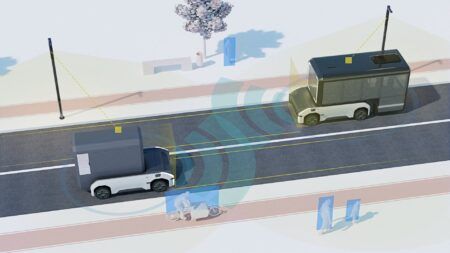

Platform 3.0 has a very sensor-rich package that makes it one of the most perceptive automated driving test cars on the road. The 200m-range Luminar lidar system, which had only tracked the forward direction on TRI’s previous test platform, now covers the vehicle’s complete 360° perimeter. This is enabled by four high-resolution lidar scanning heads, which precisely detect objects in the environment, including notoriously difficult-to-see dark objects. Shorter-range lidar sensors are positioned low on all four sides of the vehicle; one in each front quarter panel, and one each on the front and rear bumpers. These can detect low-level and smaller objects near the car, such as children and debris in the roadway.

Production of Platform 3.0 vehicles begins this spring at Toyota North America’s R&D headquarters in York Township, Michigan, which has expertise in low volume, specialized production. Volume is intentionally low to allow for continued flexibility given the quickness with which TRI has progressed in updating its test platform. There have been three major updates, including two new generation test models, in less than a year, and TRI anticipates continued rapid developments.

A share of the new test vehicles will be assembled with the dual cockpit control layout that TRI debuted last summer. This arrangement is for testing TRI’s Guardian approach to automated driving, experimenting with effective methods to transfer vehicle control between the human test driver and the automated system while maintaining a safety driver as a backup. Single cockpit vehicles are used to test Chauffeur, which is TRI’s approach to full vehicle automation. Both Guardian and Chauffeur test vehicles use the same technology stack of sensors, cameras and software.