Highways England (HE) plans to revolutionize construction and maintenance schemes on the strategic road network by introducing the use of connected and autonomous plant (CAP) equipment, using analysis and practical trials led by the UK’s Transport Research Laboratory (TRL).

HE has a vision to successfully harness the benefits of deploying highly automated construction vehicles and equipment. For this innovation project under the agency’s technical leadership, TRL will bring together stakeholders from industry and academia to support the delivery of a roadmap, through a focused and collaborative development program. Earlier this month, HE revealed that it is testing the use of autonomous dump trucks on the A14 improvement scheme in Cambridgeshire. (See here).

A research team led by TRL will initially identify the key technological and strategic milestones needed to achieve HE’s Digital Roads agenda, to implement intelligent and automated practices by 2050. The project will explore the worker safety and welfare benefits, as well as benefits related to construction quality, productivity and costs that arise through automating activities that currently require human intervention. TRL will then lead a field demonstration of cutting-edge CAP technology to test these benefits in reality.

“Our first priority is safety; for those using our roads, and for those who work there. We see the potential for great benefits of greater automation of vehicles to deliver improved safety and increased mobility,” explained HE’s innovation supply chain manager for safety, engineering and standards, Muneer Akhtar. “Connected and autonomous construction plant has huge potential to reduce the risk for construction workers and improve productivity. As a leading construction client, we are committed to working across industry to advance this emerging technology as part of our £150m (US$189.4m) innovation designated fund.”

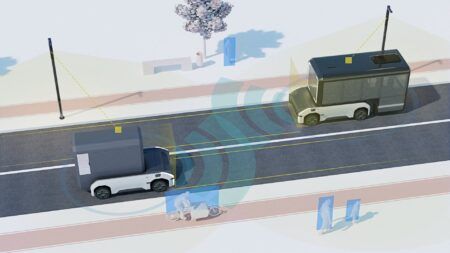

Commenting on the new project award, TRL’s chief technologist, Alex Wright, said, “Previous research has demonstrated a link between CAP and reduced risk to worker safety during excavation practices. Findings suggest that significant social and financial benefits would be delivered through the introduction of automated methods of detecting hazards and alerting operators of excavation systems, to avoid asset strikes. This has provided a baseline of what CAP can achieve, but its potential is much greater. CAP could also be introduced to benefit wider construction activities. Location-based technologies could improve monitoring and sensing of workers across construction sites, to reduce general exposure to hazards from site vehicles and vehicles driven by the public, for example.”

Wright continued, “These technologies could also enhance the construction process; through improved logistics for plant, control of plant vehicles to constrain movement, and to benefit the construction of road pavements via the delivery of smoother and better compacted surfaces. However, CAP’s rate of development has been slow to date and as a result adoption of such innovations are missing from operational standards, leaving the industry unclear about the opportunities available. By initiating this project, we can address the issues and determine how this powerful new technology can best be applied to bring about positive, tangible change and revolutionize the industry as we know it.”