WorldAutoSteel, the automotive group of the World Steel Association, has unveiled its plans to launch Steel E-Motive – a new vehicle concept for Mobility as a Service (MaaS), which represents a big step forward in making autonomous ride sharing and ride hailing vehicles an affordable and sustainable reality, and promises emissions reductions of up to 86%.

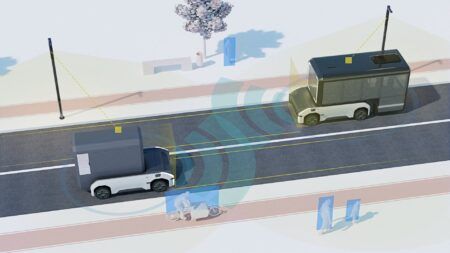

According to WorldAutoSteel, Steel E-Motive is the world’s first autonomous vehicle engineered to meet global high-speed crash requirements, with a performance in line with an IIHS Good rating. Drawn from a portfolio of 64 advanced high-strength steel grades, Steel E-Motive features seven AHSS structural innovations, including a battery pack structure that is 37% lighter than average.

It is the latest evolution in a line of AHSS steel-enabled concepts from WorldAutoSteel that began with ULSAB (Ultralight Steel Auto Body) in 1998.

With the aim of demonstrating how steel has a vital role in achieving a zero-emission transport future, WorldAutoSteel will make its Steel E-Motive portfolio of materials and methods freely available to automotive manufacturers around the world to help them produce a new generation of efficient, economic, and sustainable vehicles that could reduce in-use emissions by up to 86%, when used with renewable energy contributions and high occupancy rates of more than three passengers.

Steel E-Motive will be presented at several high-profile industry events and exhibitions in the UK, Europe and USA, including Zemo Partnership in London in June, CAR MBS in the US in August, EuroCarBody in Germany in October, and CoMotion LA in Los Angeles in November.

Delegates to these events will see a 3D printed prototype of the Steel E-Motive (SEM1), a four-passenger concept for urban commuting, alongside an augmented or virtual reality presentation. A series of technical presentations will also take place in 2023, in countries including Japan, Korea and China.

“We will be presenting a highly engineered vision of the future for MaaS,” explained Cees ten Broek, director of WorldAutoSteel. “Our mission with Steel E-Motive is to provide a roadmap of innovations that will advance and enable the journey to zero emissions. Steel’s characteristics of strength, durability, and repairability align with the needs of these next generation ride sharing and ride hailing vehicles, while supporting optimal total cost of ownership.”

Steel E-Motive can be produced using existing global manufacturing and supply resources at attractive cost levels and profit margins, making it possible for production to start as soon as 2030, the firm noted. Production emissions are significantly reduced through a design that minimizes material thickness and maximisers material utilization.