Australian connected vehicle technology developer Cohda Wireless is applying its V2X (Vehicle-To-Everything) technology to develop an advanced truck platooning solution, with ongoing research projects in Europe and its home country.

As the only company to have integrated its V2X software into two car manufacturer platforms, Cohda believes the adaptation of its unique technology for the trucking industry will help shape the introduction of global truck platooning standards such as those being developed by the ENSEMBLE project in Europe. Its V2X applications are already the most widely deployed in the industry, and it expects that by 2021, over a million vehicles will feature Cohda technology whilst it continues to secure infrastructure deployments across the USA, Europe and Australia.

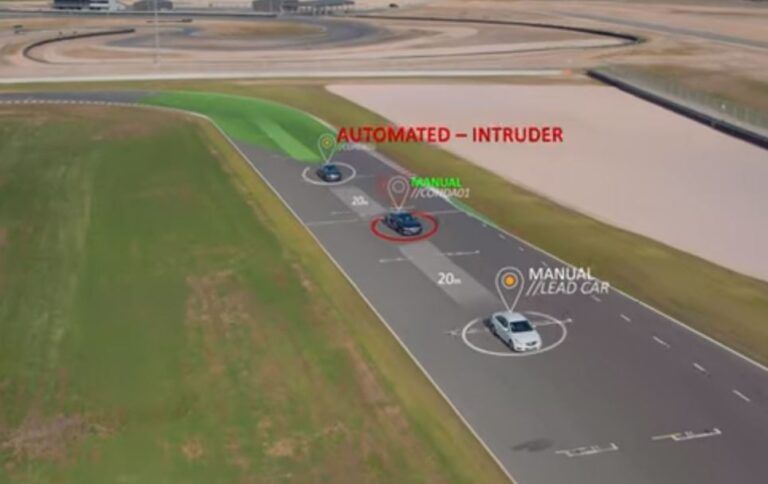

Cohda recently conducted rigorous testing of its technology at Australia’s newest motor-racing circuit, the Bend Motorsport Park, just outside Adelaide. The tests confirmed Cohda’s platooning system can deliver impressive gap management of 16 feet (5m) +0.4 seconds at 59mph (95km/h), and can also overcome many of the connectivity challenges of platooning recognised today. In a typical platoon consisting of three vehicles, the truck in front lays a virtual track for the others to follow by relaying its position up to 30 times per second to the trucks that are following, which are then at liberty to join and re-join the platoon as they wish without destroying the integrity of the platoon connection. Robustness to ‘intruders’ or trucks leaving from the middle of the platoon will be a unique and valuable feature.

Cohda’s breakthrough V2X-Locate positioning system was developed to enable accurate vehicle positioning in areas where GNSS positioning performance degrades such as urban canyons, tunnels, parking garages and other scenarios with compromised sky views. This technology has been applied to make the platooning system impervious to weather conditions such as heavy rain or fog that might affect other sensor performance. Cohda’s platooning solution will also allow for coordinated braking where trucks are simultaneously aware of the need to brake as opposed to braking taking place in a ‘daisy-chain’ fashion when sensors are in play.

“We are fast-tracking the development of the platooning solution, which is in several ways, unique. We are developing a robust solution that can accommodate departures and intruders,” explained Dr Paul Alexander, Cohda’s chief technical officer. “In practical terms this means that trucks can leave and re-join the platoon at will without affecting the integrity of the platoon. Another important distinction with our system is that it is ‘fail operational’ because accurate vehicle positioning, particularly spacing, is governed by our unique V2X-Locate technology as opposed to a reliance on on-board sensors.”

Alexander added, “We received positive feedback from truck OEM company leaders during our recent tour of Europe. We believe we can produce a compelling and cost-effective proposition that will advance the introduction of truck platooning on our roads, and achieve its objectives of improved fuel economy, reduced driver fatigue and traffic congestion.”