The USA’s Auburn University and two of its research partners, FPInnovations and Transport Canada, have made history by conducting the first ever on-road commercial truck platooning trials in Canada.

Featuring an electronically linked convoy that consisted of two heavy-duty transportation trucks, the research partners conducted successful highway platooning tests in October and November on routes around Montreal and surrounding areas in Quebec.

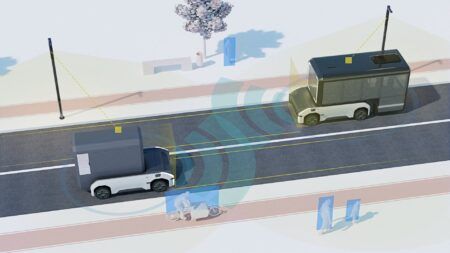

Truck platooning is an emerging fuel-saving vehicle technology in which the trucks, driven in a convoy, are linked by a computer system that maintains the desired distance between them by controlling acceleration and braking, reacting faster than a human driver usually can.

Drivers were at the wheels of both trucks the entire time during the trials, but in the future, it may be possible for only one driver to be at the wheel of the lead truck, followed by a number of driverless automated trucks.

Auburn has tested its truck platooning technology on highways in the USA before, but these tests offered a new environment for testing. The University of Alabama partnered with Transport Canada to cover the legislative and safety aspects of the trials. The other partner, FPInnovations, is the not-for-profit innovation agency that conducts research and development activities in support of the Canadian forestry industry.

Auburn has tested its truck platooning technology on highways in the USA before, but these tests offered a new environment for testing. The University of Alabama partnered with Transport Canada to cover the legislative and safety aspects of the trials. The other partner, FPInnovations, is the not-for-profit innovation agency that conducts research and development activities in support of the Canadian forestry industry.

FPInnovations is keen to trial the potential benefits of platooning for the country’s logging sector. During the trials, a distance of between 65ft and 100ft (20-30m) was kept between the two trucks, which enables a passenger vehicle to safely cut in between the vehicles. The truck platoon traveled several hundred miles on highways with normal vehicular traffic.

“The system combines sensors, measurements from a radar and GPS data with other vehicle information such as brake and throttle status shared over a dedicated short-range communication (DSRC) radio in order to maintain accurate gap spacing and enable safe platooning,” explained David Bevly, a mechanical engineering professor and director of Auburn’s GPS and Vehicle Dynamics Laboratory. “We believe the testing we were able to perform in conjunction with our Canadian partners helped us move forward in validating the technology. Specifically, it provided us with a unique opportunity here to test in conditions that were new to us, and we are grateful for the assistance of Transport Canada and FPInnovations.”

James Johnson, one of the truck drivers and a research engineer at Auburn, noted, “We have run the trucks under different weather scenarios before, but this was a first for us in terms of experiencing a combination of rain, ice and snow. The automated braking and acceleration worked well under the weather conditions, and we were pleased with how the trucks performed throughout the testing.”

Édouard Proust, a PIT Group engineer with FPInnovations, added, “Auburn’s system proved to be very reliable even in the rainy and snowy conditions we experienced. We were able to spend most of our time on the road with the platooning mode engaged. It’s a little soon to make a conclusion on the data that was gathered, but the system reacted properly to vehicle cut-ins and to road conditions.”