According to a new study led by Rutgers University in New Jersey, keeping highway pavement in good condition saves money and energy and reduces greenhouse gas (GHG) emissions, while more than offsetting the pollution generated during road construction.

The study was led by researchers at the Rutgers School of Engineering in New Brunswick, and involved their collaborators at North Dakota State University and Al-Mustansiriyah University in Iraq, with the research published by the International Journal of Sustainable Transportation.

The researchers found that extending the life of pavement through preventive maintenance can reduce greenhouse gases by up to 2%; transportation agencies can cut spending by 10-30%; and drivers can save about 2-5% in fuel consumption, tire wear, vehicle repair and maintenance costs because of smoother pavement surfaces. The research will help transportation agencies choose appropriate maintenance strategies that consider environmental impacts in decision making.

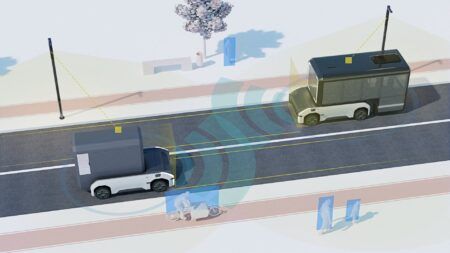

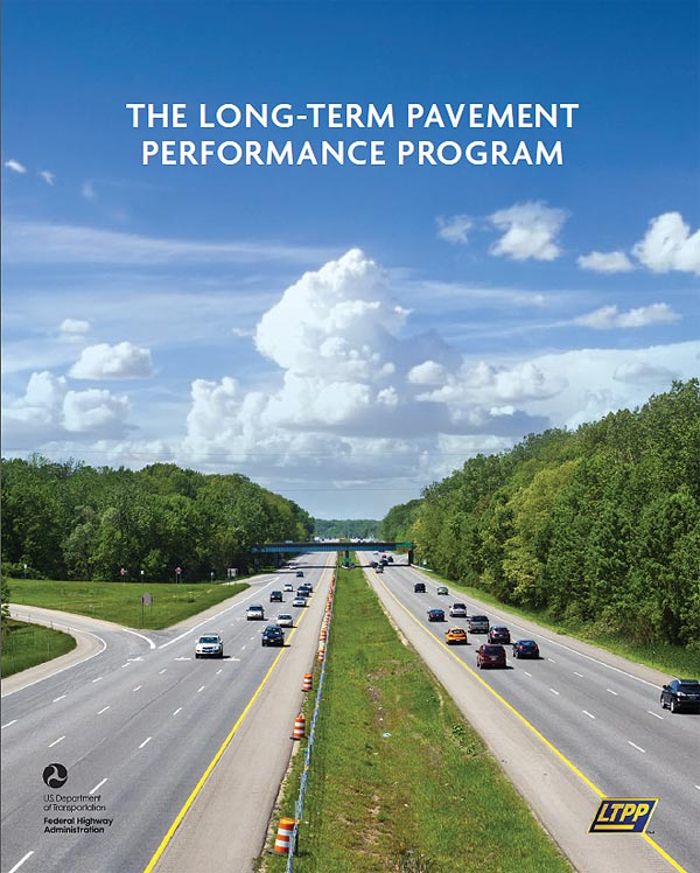

The transportation sector is the largest source of GHG emissions, primarily carbon dioxide (CO₂) from cars, trucks and buses. The researchers used the long-term pavement performance (LTPP) database maintained by the US Department of Transportation’s (USDOT) Federal Highway Administration (FHWA) to measure the environmental impact of roadway repairs, especially preserving asphalt pavement, in terms of CO₂ emissions linked to global warming.

The transportation sector is the largest source of GHG emissions, primarily carbon dioxide (CO₂) from cars, trucks and buses. The researchers used the long-term pavement performance (LTPP) database maintained by the US Department of Transportation’s (USDOT) Federal Highway Administration (FHWA) to measure the environmental impact of roadway repairs, especially preserving asphalt pavement, in terms of CO₂ emissions linked to global warming.

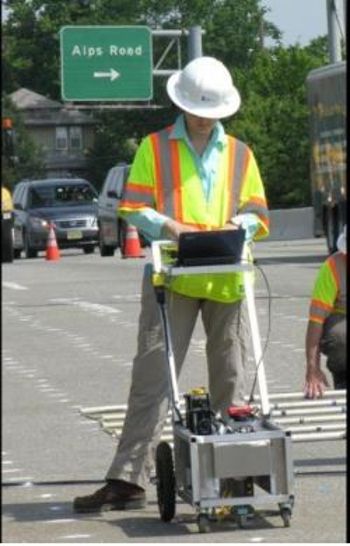

At the construction stage, the study noted that there are significant differences in emissions caused by various preservation treatments mainly due to different raw material components and manufacturing processes. At the highway use stage, fuel consumptions vary significantly depending on tire rolling resistance that is affected by pavement surface characteristics. The CO₂ emissions at the use stage were predicted using the US Environmental Protection Agency’s (EPA) Motor Vehicle Emission Simulator (MOVES).

The study used a full lifecycle approach (LCA) to look at the carbon footprint of common ways to preserve pavement. The commonly-used treatments studied include:

- Thin overlay – placing up to 2in (5cm) of asphalt on roads;

- Chip seal – spraying asphalt emulsion on pavement and laying aggregate;

- Slurry seal – spreading a slurry over pavement;

- Crack seal – filling cracks with rubberized asphalt or polymer-modified asphalt with some filler.

The study found that thin overlay leads to the greatest overall reduction in CO₂ emissions (2%), because of a large decrease in road roughness. The crack seal method led to the lowest emission reduction (0.5%), but all preventive maintenance methods reduce emissions overall. The researchers further developed the lifecycle assessment tool for evaluating the environmental impact of roadway projects.

“When pavement is in its early failure stage, preventive maintenance can restore performance and extend pavement life with lower costs,” explained the study’s lead author, Dr Hao Wang, an associate professor who focuses on infrastructure engineering in the Department of Civil and Environmental Engineering at Rutgers University. “Pavement preservation leads to significant environmental benefits due to the improved surface condition, which results in smooth pavement, saves energy and reduces user costs.”