The Michigan Department of Transportation (MDOT) and the Michigan Technological University have developed a mobile 3D optical evaluation system to help assess the state’s reinforced concrete bridge decks with fewer impacts on the traveling public.

Developed with researchers from the Michigan Tech Research Institute (MTRI), the new technique allows MDOT inspectors to collect more accurate data within a safer working environment. With 75% of Michigan’s highway bridges 40 or more years old, using sound asset management tools is critical for preserving the road network. MDOT routinely inspects concrete bridge decks as required by national standards, which typically requires a visual inspection from the shoulder of the roadway, outside the traffic flow. Damage often starts as surface cracks that can expose the steel reinforcement to road salt and water, causing corrosion, spalling and subsurface fractures. Traditional inspections from the shoulder might miss subtle hairline cracks.

A new system allows inspectors to scan fine details of bridge decks at near-highway speeds without the need for lane closures or exposing workers to traffic hazards. The 3D optical bridge evaluation system (3DOBS) uses a vehicle-mounted camera and image analysis software to supplement traditional inspections. In earlier phases of this project, MDOT tested a digital still camera, which had plenty of resolution to pick up details, but lacked the necessary frame rate. Researchers then tried an updated version of 3DOBS that uses a professional cinema-grade RED Helium 8K S35 digital camera. Attached to a truck by a custom MDOT-built mount on a standard trailer hitch, the new camera can capture high-quality video images and spatial orientation data at near-highway speeds under real-world conditions.

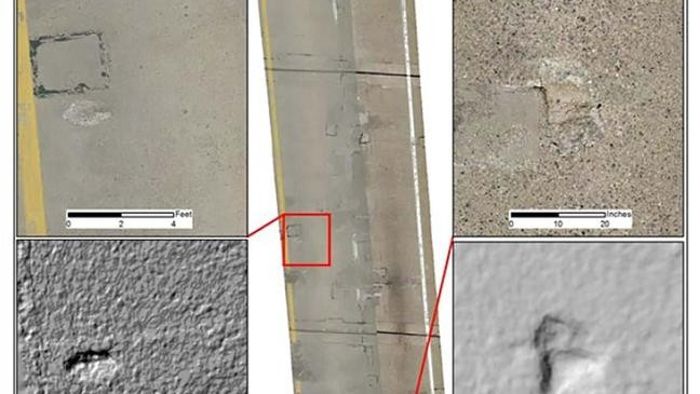

After the data is collected, the software can generate two types of output: a 2D mosaic stitched together from many individual images or a 3-D model of the bridge deck. The system allows inspectors to pinpoint deck deficiencies, offering information that can supplement other inspections. Routinely collecting imagery of bridge decks with 3DOBS will help MDOT gain a better understanding of deterioration rates, allowing repairs and preservation treatments to be performed at the optimal time.

“The big difference is that this camera offers full-resolution images at 60 frames per second,” explained MTRI’s Richard Dobson, the principal investigator on the project. “That capability makes the difference between being able to scan a bridge deck at 5mph versus 45mph. At 35.5 megapixels, with the camera nine feet above the ground, we can put a lot of pixels on a spot. The two biggest advantages to this system are that there’s very little disruption to traffic and you don’t expose inspectors to traffic. There are other advantages to this method as well, including speed and accuracy. The new camera was able to resolve cracks down to 1/64th of an inch. The typical data collection time for an average sized bridge deck is 30 minutes or less.”

MDOT’s project manager, Bandon Boatman, commented, “This project provided innovative technology to supplement routine bridge deck inspections while creating a safer working environment for bridge inspectors. We will continue to evaluate the 3DOBS technology this summer to see how it best fits it into inspection workflows.”