A new technology partnership is aiming to transform road tolling for both providers and motorists alike by using the latest advances in lidar technology and data analytics to identify and classify vehicles at highway speeds.

In order to classify the type of vehicle required to ensure that the correct fee is charged, traditional tolling systems often depend on physical infrastructure to reduce vehicle speed, or tollbooths to allow for manual processing, which can cause congestion and frustration among drivers. Advanced systems that allow for faster tolling, however, are often subject to abuses such as leakage, while road-based sensors often fail due to wear and tear. California-based developer of low-cost lidar systems, Cepton Technologies Inc. has collaborated with industrial perception and machine learning systems integrator, MechaSpin, to develop a lidar-based solution that produces detailed 3D classification of vehicles in real-time for automated tolling applications.

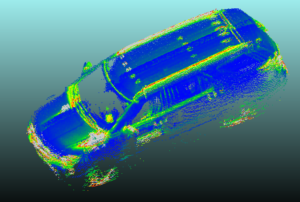

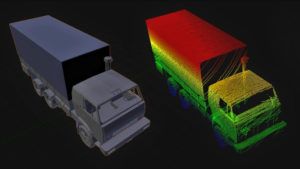

The next-generation solution combines Cepton’s Sora-P60 lidar unit with MechaSpin’s MSx software to enable immediate profiling and classification of vehicles at highway speeds in a wide range of weather and lighting conditions. The partner’s solution addresses many vehicle identification challenges in tolling situations by eliminating the need for physical infrastructure while providing accurate data, such as vehicle velocity, size and axle count, in a format that can be integrated with other sensor, data capture and billing systems. At the same time, the hardware is designed for aerial installation and contains minimal moving parts, reducing the likelihood of failure.

The next-generation solution combines Cepton’s Sora-P60 lidar unit with MechaSpin’s MSx software to enable immediate profiling and classification of vehicles at highway speeds in a wide range of weather and lighting conditions. The partner’s solution addresses many vehicle identification challenges in tolling situations by eliminating the need for physical infrastructure while providing accurate data, such as vehicle velocity, size and axle count, in a format that can be integrated with other sensor, data capture and billing systems. At the same time, the hardware is designed for aerial installation and contains minimal moving parts, reducing the likelihood of failure.

Founded in 2016, Cepton is the only company in the industry to ship high-performance and low-cost lidar sensors directly to customers. The company’s Micro Motion Technology (MMT) is unique to the industry, as unlike traditional laser beam-steering technologies, such as spinning lidar and micro-electronical mechanical systems (MEMS), the MMT architecture enables a mirrorless, frictionless and rotation-free system to increase the durability, reliability and manufacturability of the product, while delivering industry-leading range and resolution for highly accurate 3D sensing. MechaSpin’s MSx Processing Engine provides advanced signal processing and machine learning algorithms for 3D lidar data. The company’s software has been developed to be sensor agnostic and works with data from a large variety of sensors and vendors.

“Our partnership with MechaSpin is founded on both businesses’ deep understanding of the unique and powerful capabilities of lidar, especially when it is teamed with problem solving software solutions,” said Neil Huntingdon, Cepton’s VP of business development. “We believe that this partnership will bring major innovations to the tolling industry. Our Sora-P60 lidar delivers an unrivalled scan speed at 380Hz, making it possible to profile vehicles as they pass at highway speeds. Our partnership with MechaSpin will allow for faster, more accurate and lower cost management of our transport infrastructure as the number of vehicles continues to grow globally.”

MechaSpin’s president, Danny Kent, added, “The tolling industry lacks an integrated end-to-end solution for deploying 3D lidar for vehicle classification and tracking. We have partnered with Cepton to deliver a solution for this need. Their lidar technology coupled with our MSx Processing Engine offers a robust solution for tolling, intermodal and other transportation industry applications.”