The USA spends US$5bn a year to repair damages to road infrastructure from winter snow and ice control operations and the use of traditional de-icers, however, a team of researchers at Washington State University (WSU) is developing a more sustainable solution using grape skins and other agricultural waste.

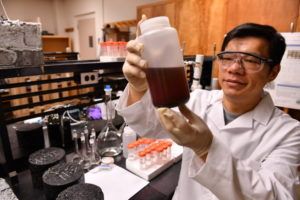

The WSU researchers, including graduate student Mehdi Honarvar Nazari and associate professor of civil and environmental engineering, Xianming Shi, determined that their de-icer containing grape extract outperformed commonly used de-icers, including road salt and what is thought to be a more environmentally friendly blend of salt brine and beet juice. They published their results in the December issue of the ‘Journal of Materials in Civil Engineering’. Every year, roughly 27 million tons of road salt (sodium chloride), is used on USA roadways for winter maintenance. The chlorides do not degrade in the environment and may pose long term environmental risks.

Commercial de-icers typically contain chemicals that are corrosive toward metals, asphalt, concrete, and pose some risk to aquatic species. Beet juice has become a common additive used by highway departments and cities to enhance the performance of de-icers while reducing their corrosive impacts. However, when beet juice enters water bodies, it can deplete oxygen and endanger aquatic organisms. Working to develop a greener additive, the WSU researchers derived chemicals from waste grape skins through chemical degradation and natural fermentation. The researchers found that their grape extract-based solution melts ice faster than other de-icers and causes significantly less damage to concrete and asphalt, the two standard materials used in bridges and roads. The solution also poses less risk to nearby water bodies.

Shi first thought of using biotechnology to derive de-icer additives out of agricultural waste materials several years ago when tasked by the Alaska Department of Transportation to develop locally sourced and performance-enhanced brine formulations for anti-icing. His group has also successfully applied this technology to waste peony, sugar beet, and dandelion leaves, as well as waste from apples and grapes. The WSU team’s work was supported by the National Science Foundation (NSF), the Washington State Department of Transportation (WSDOT), and the US Department of Transportation (USDOT).

“We delivered a more sustainable solution because we’re introducing less chlorides into the road operations and are achieving comparable or better performance. Our process to make the formula produces no waste of any kind,” Shi said. “It’s one step in the right direction. The beauty of this approach is that it allows us to diversify. We can use this same platform technology in different regions of the country but choose a different agricultural product, depending on what source of waste is available.”